In an ideal world, all audio would be produced in purpose-built studios that would allow for perfect isolation and accurate monitoring across the entire frequency spectrum. Unfortunately, the economics of the music industry have long made this scenario all but impossible for the studio masses. In fact, a great many audio professionals work remotely in rented spaces or private homes that were never designed with music production in mind. So what can be done to turn a less-than-ideal space into an accurate recording environment?

To answer this question, Mix tapped five studio designers who have worked on a wide variety of projects, ranging from complete remodels to semi-permanent improvements of existing spaces. Our experts — George Hallowell of Studio Pacifica, Chris Pelonis of Pelonis Sound and Acoustics, Richard Schrag of Russ Berger Design Group, Larry Swist of Lawrence P. Swist Designs and Carl Yanchar of Wave:Space — talk about many of the obvious and not-so-obvious acoustic problems that plague the average project studio and share which commonly available surface-treatment products can best mitigate these issues.

FASHION OVER FUNCTION

It probably doesn’t come as a shock that some of biggest acoustic problems in the average project studio stem from a lack of physical isolation and poor low-frequency management. Many project studio owners also fail to solicit reputable advice and embark on ill-conceived improvement projects that often end up doing more harm than good.

“Noise intrusion is one of the biggest issues,” explains Swist. “Eventually, even the most sample-oriented productions need a vocal or some live recording, which usually ends up being the most dominant element in a production. Historically, the goal in studio design has been to achieve a recommended NC, or noise criteria value, between 15 to 20 in both the control room and the live room. If you own a sound-level meter, this is equivalent to an A-weighted sound pressure level measurement between 23 and 28 dBA. Most project studios don’t have the luxury or budget to have sufficient isolation systems incorporated into their design, and consequently the operators have to contend with all the gear and drive noise, air-conditioner noise, birds, dogs, traffic and the unfortunate occasional event within the plumbing system.”

“One common error in the treatment of a cost-effective project studio is to cover the walls with 1-inch-thick foam and carpet the floor to reduce the reverb time and to hide or reduce any parallel wall reflections,” Hallowell adds. “Most small rooms, in fact, need only relatively small amounts of absorption to attain satisfactory reverb times. The absorption needs to be placed in the right positions and be of the correct type and thickness to keep the absorption relatively equal at all frequencies. Carpet and thin foam absorb high frequencies quite effectively, but it is very difficult to absorb low frequency with foam or Fiberglas unless it is quite thick or spaced far away from the wall — both difficult [to achieve] in a small room. There are corner foam products that are eight inches thick or so, but at very low frequencies, the air particle velocity nears zero as the wave approaches the wall, so products that work by slowing the air particle velocity, like foam or Fiberglas, will not be very effective. Low-frequency [energy] is more effectively absorbed, especially in small rooms, with membrane, panel or Helmholtz absorption, such as RPG’s Modex unit.

“A third common problem is the lack of diffusion in project studios,” Hallowell continues. “The goal in the treatment of the room is not to make the room acoustically disappear. Some of the ‘sound’ of the room is both necessary and unavoidable. Remember that the goal of any well-treated room is to make the recording or mix in the room relatively flat and reproducible. That is to say, whatever you record in that room should sound the same no matter where it is played back. As it is necessary to absorb the right amount at the right frequencies, it is also necessary to provide the right amount of diffusion in the correct places.”

“Another problem I see is the pouring of money into projects at the direction of Websites, news groups and blogs,” Pelonis adds. “It takes an extremely rare and gifted individual who can wade through [all of that] and somehow glean the correct information to create a thriving, true and functional design. Please don’t take this the wrong way; I am a huge fan of shared information on the Web. I occasionally browse through the discussions, and there is quite a bit of correct information out there and some very well-intentioned, qualified people providing it. The problem is that there is also a lot of BS. Acoustics is a very deep subject.”

THE NEAR-FIELD MYTH

With the availability of so many self-powered stereo and multichannel monitoring systems, as well as the deluge of accompanying marketing hype, many users have been lulled into a false sense of security when it comes to the accuracy of their studio. “The use of near-field monitors does reduce the sound of the room, but it can also create other potential concerns,” Hallowell says. “First of all, the use of near-field monitors does not remove the room sound. If it did, you would be mixing in an anechoic chamber. The room still has an effect.”

“Even with near-fields, if the monitors are loud enough for you to hear them, they’re loud enough to interact with the room,” says Schrag. “For all the reasons that people find mixing on headphones to be unreliable, if the room doesn’t play a part in what you hear, then it will be difficult to judge how imaging and panning and any spatial feel will be experienced by listeners who do play the music in real rooms.”

Speaker placement and orientation are also extremely critical issues that can create a whole host of other problems if not properly addressed. “Case in point: I was setting up a studio that we had just completed, and the owner had these MTM configuration monitors, with the tweeters in the middle and the mids on either side,” says Yanchar. “And they had oriented the speakers horizontally, and, of course, there were horrendous phase cancellations because of that. So even the orientation of the speaker is critical when you’re that close.”

Thankfully, there are some very easy ways to check for proper speaker placement and make corrections for issues such as boundary effect, a common problem for speakers that are not soffit-mounted. Both Pelonis and Hallowell recommend using some widely available software applications that are designed to tackle these exact problems. “RPG has a very cool program called Room Optimizer,” explains Pelonis. “It will display a simulation of the effect of boundary interference with varying speaker/listener positions that are user-definable. I think it’s worth the cost of admission just so people can understand the truth of what they’re up against from a scientific standpoint. Subtle changes can have not-so-subtle results.”

“Near-field monitors should also be located far enough away from the listener so that the soundfield from both, or all of the speakers in the case of 5.1, has time to blend,” Hallowell adds. “Also, remember that all speakers should be the same distance from the listener and the correct angle in plain view. It is also a good idea to not mount the monitors on the table or console so that you do not get immediate reflections off the console or furniture.”

READ: More Sage Advice

FINDING THE FIX

Even after identifying the chief problem areas within a studio, there is still the task of determining which materials will solve certain problems and how much of a given acoustic surface treatment is needed. And to further complicate things, each material has its own inherent strengths, weaknesses and special mounting needs.

“For absorption at midrange and high frequencies, there are myriad possible materials that can be used,” explains Hallowell. “We have used a number of products, including compressed Fiberglas, commonly available as Owens-Corning 703 or 705 insulation board, which is inexpensive, easy to work, but sheds fibers in the air. We’ve used acoustical cotton, which is similar to Owens-Corning 703 but produces fewer fibers. There is acoustical foam such as Sonex, sintered or foamed aluminum, Fiberglas duct liner, carpet, drapery and many other products. When using products that can release particles into the air, like Fiberglas, it is a good idea to cover the Fiberglas with an acoustically transparent material like panel fabric. For any product you have in the room with you, you should also be aware of how flammable it is.

“The above types of absorptive treatment can vary dramatically as to how much they absorb and at what frequencies,” he continues. “Most of that information is available online at the manufacturer’s Website. Once you know how much is absorbed and at what frequency, you should calculate a rough idea of the final reverb time for the room using manual calculation or a software calculator. Each product you select can also be adjusted in terms of the frequencies absorbed by using thicker versions or leaving a gap of various dimensions behind the absorber to increase low-frequency absorption.”

“These products absorb energy by means of friction, which means that they are only effective when placed in the area of a wave’s maximum particle velocity and not its maximum sound pressure,” adds Swist. “Any frequency’s energy that is not transferred though a boundary will have a particle velocity of zero at that boundary and a maximum particle velocity at a distance of one-quarter of its wavelength from that boundary. So in practice, if someone mounts a 1-inch-thick Fiberglas panel directly on a wall, the effective bandwidth of the absorbed frequencies will only be 4 kHz and higher. So one can ascertain that the use of this type of direct wall mounting would severely color the reverberant characteristics of a room by absorbing only high frequencies and allowing the lower bands to remain uncontrolled.”

Swist explains that this problem is solved by mounting the panels away from the wall with frames or other mounting systems. “One can then calculate the effective absorption bandwidth of the panel by using the one-quarter wavelength measurement and incorporating that into the overall reverberant field design goal. Obviously, there is a limit to the distance one can mount these panels to obtain lower-frequency performance, and therefore other means are needed to control the low-frequency energy.”

Dealing with a buildup of low-frequency energy is never an easy task. The problem becomes all the more difficult to treat when dealing with the often-cramped dimensions of a spare bedroom or den that is being converted into a studio. “Low-frequency absorption treatment is a bit more specific,” explains Hallowell, who adds that there are many off-the-shelf products designed to absorb low frequencies. “Some are targeted for specific frequency ranges, such as RPG Modex, and some are more broadband, such as RPG Modex Broadband.” Hallowell stresses that whatever absorption products are installed, one should calculate the predicted quantities and types of absorption needed before installing. You can adjust the quantities and placement of the products, as needed, as you complete the installation.

“You should also consider where and how much diffusion you need in the room,” he continues. “There are a number of off-the-shelf diffusion products available, depending on your needs. A good option are quadratic residue diffusers, such as RPG Omniffusors and Diffractals, or the Auralex SpaceArray. You could also try mixed absorption/diffusion products such as RPG BAD [Binary Amplitude Diffsorbor] panels or Kinetics’ TAD [Tuned Absorber/Diffuser Panel]. You commonly see an area of diffusion at the rear of the room behind the engineer in stereo mixing rooms to get a smooth return from the back wall.”

GUESS AND CHECK?

Estimating the type and quantity of acoustic material necessary to treat a room is only one part of the equation. To make the most of any potential improvements, users must develop an understanding of where and how to apply surface treatments, as well as how to check their work and make adjustments.

“You don’t want to overuse the Fiberglas or foam because they don’t absorb low frequencies,” says Yanchar. “So the more of that that you have in a room, the more you’re boosting the low frequencies as a default. You have to balance that, which usually requires you to cover 50 to 60 percent of the room with materials like that. As far as placement, the corners are the most efficient place for countering both high and low frequencies. And then as far as reflections on the side and ceiling, the common way of optimizing the position of those materials is to have someone hold up a mirror and place surface treatment wherever you see monitors reflected in the mirror.”

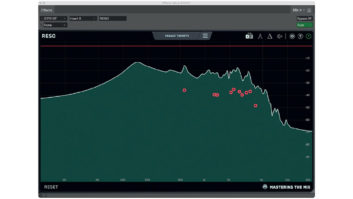

“The only quantitative way I know of checking your work is to do a real-time analysis of the room,” says Hallowell. “Whatever type of analysis you do, it can be relatively expensive and requires a certain amount of knowledge about how to test and what to do with the results. Recent years have seen more and more lower-cost test units, such as the NTI AL1 Acoustilyzer and the Sencore SP495, but there is still a cost and a learning curve. The ears of an experienced engineer are also a valuable qualitative testing tool.” Hallowell also recommends taking a recording done in your room to other familiar rooms to see how it translates. “If your mix has less bass or high end than you thought when you mixed it in your room, you may need some renovation.”

BEST-CASE SCENARIO

While owning a purpose-built, professional project studio may be out of the reach of most working professionals, treating an existing room can yield some surprisingly good acoustic results. “Some rooms were designed well in the first place, whether by luck or good planning, so the best-case scenario might be only minor tweaking to get your desired sound,” Hallowell says. “If the room has good mode characteristics and sufficient noise isolation, then it may only need minor tweaking of the surface treatments or re-arrangement of the near-field monitor placement.”

“You can actually do a fairly decent job and get pretty good results,” adds Yanchar. “Basically, it all falls apart at some low frequency because of the space available. We’ve done some rooms in some very tight spaces that actually perform as well as or close to the biggest rooms we’ve done.”

“The best-case scenario is staggeringly good,” concludes Pelonis. “I have been custom-designing prefab, modular acoustical systems for decades. I have several projects every year that fit this description. If there is one thing I’d like to impress upon your readers it is the value of talking to a professional designer to help them with the treatment specifications, whether it’s custom-designed or off-the-shelf. I think that many designers are open to working with situations that, for whatever reason, don’t have the option of a complete build-out.” n

Robert Hanson is a former editor at Mix and Remix.

Step by Step: D.I.Y. Acoustics

Although it’s impossible to account for the myriad variables that come into play when attempting to treat the acoustics of a project studio or production environment, designer Larry Swist has broken the process down into four basic steps that can serve as a rough guide for anyone who is interested in improving the sound of their workspace.

- Start by eliminating as much noise intrusion as possible. Place CPUs and hard drives in a separate room or closet, or purchase or fabricate some sort of soundproof enclosure. This is especially important for users who record live tracks within the control room.

- Create a wide-bandwidth absorptive surface in the front of the control room, right behind the monitor system. Special emphasis should be placed on creating a cavity in the corners that can be packed with high-density Fiberglas to obtain some bass-trapping effect. This usually has a profound effect on accuracy and imaging quality.

- Create a back wall in the control room with as many random surfaces and varying depths as possible. This will help create a more diffuse reflective condition. Many QRD-type diffusers are available on the market, but it’s possible to approximate this effect with bookcases, CD racks and shelving. This approach does not conform to a specific number theory, and thus it does not have a predictable effect as with real QRD diffusers. And as with the front of the control room, it is extremely beneficial to try to provide some form of bass trapping in the back corners, as well. This can be done with a number of approaches, including framing and panels.

- If you have the luxury of enough ceiling height, it is beneficial to install an absorbent cloud system that hangs from the ceiling (at least over the console and mix position). These can be made from 2-inch, fabric-wrapped, high-density panels suspended on hooks and wire. Be sure your ceiling can take the added weight and that you mount these panels securely.

— Robert Hanson