Figure 1: Inside the Digidesign 002, a view of the power supply (normally located on the back panel) and its wiring harness. Power is distributed to the system, I/O (FireWire and MIDI) boards and faders, in the case of the controller version.

Mods, hot rods, tricked-out and tweaked — equipment alterations and modifications are very much an extension of the maintenance/repair process, a variation of the axiom “necessity is the mother of re-invention.”

The geek inclination to modify is inspired and motivated by three primary issues: reliability, serviceability and performance. For example, when technicians continually see the same problem, they tend to create a modification to improve reliability.

Mass-produced gear is typically de-signed for ease of assembly, not necessarily for ease of repair or serviceability. As incredible amounts of processing power are squeezed into ever-tighter spaces, the lengths of interconnecting cables are such that most products cannot be both disassembled and tested without the use of extender cables, limiting the cost-effectiveness of repairing, for example, subminiature portable DAT recorders.

Performance is the other mod motivator — whether you want to give modern gear a vintage sound, upgrade the signal path (with better op amps, caps and resistors) or creatively add or delete features. While such upgrades can enhance your gear’s abilities, I always advise customers to make sure that those “custom” items — particularly console pots — are still available (and affordable!) before investing labor and parts in the upgrade process. Improved caps and op amps can spotlight the poor performance of other components, such as bad pots and switches.

POWER SUPPLY CONNECTIONS

The power supply is one of the first places to consider for potential improvement, specifically in terms of heat dissipation and power distribution. (Look for discolored PCBs.) And while serviceability is encouraged, the connectors that make power supply modules, circuit boards and ICs easy to replace are also a potential problem. Vintage MCI tape machines are well known for their interconnect issues. Look for broken/intermittent connections where a Molex is soldered to the PC board.

Digital circuits require an exceptional amount of power. If the interconnect system is not up to the job, then the product will eventually have mysterious symptoms that seem to be “fixed” by power cycling or connector reseating and eventually evolve into a catastrophic failure. I’ve seen this with ’80s-era digital outboard gear from Lexicon, Eventide and Neve, as well as the Alesis BRC.

Thanks to surface-mount technology, the reliability of super-complex circuitry is generally improved, yet it can easily be compromised by poor power/ground distribution or vulnerability to static electricity. As cool as workstations are, interfacing computers, hard drives and audio interfaces adds a new dimension to minimizing system noise — a topic for future exploration. Feel free to e-mail me ([email protected]) your noise issues.

Figure 2 (top): The original Molex-style connectors are bifurcated—they make contact in two places—but the number of contacts and contact pressure are borderline inadequate for the current demand, hence the more robust connector (above). The “dots” are contact points, two per side.

NEW AND OLD

Not everything that exhibits service issues is vintage. These can also crop up in more recent products. For example, the Digidesign 002 (rack and controller) had a power distribution problem that was resolved a year or so ago. If you’re experiencing communication or buffer-size error messages, one possible solution is to remove the bottom cover and exercise and reseat all of the connectors. (See Figs. 1 and 2.) Assuming you feel that you can handle such routines (if you don’t, then please seek qualified help), before you start, remember to unplug the unit, be fully dressed and stay out of the bathtub during this electro-aerobicising. Keep in mind that manufacturers cannot take responsibility for your carelessness.

Note: According to Digidesign’s Website, any customer experiencing this failure on an 002 product (in or out of warranty) will receive a new Molex power harness at no charge. This offer is good for as long as you own your 002. If you require a new harness or would like one as a spare, contact Digidesign’s tech support for a return authorization (RA) number.

A neophyte Pro Tools user, I blamed other intermittent problems on the 002 harness issue. (I’m running Pro Tools on a Sony VAIO laptop at the school where I teach.) Having exercised and replaced harnesses on more than one 002, I chose a more extreme approach for my system: hardwiring one end of the harness directly to the power supply because that connector was under the greatest amount of stress. When that did not resolve my intermittent problems — the annoying “change the buffer size” dialog box — I began to look elsewhere and asked a lot of questions. Things are better now.

SOFTWARE ISN’T THAT HARD

As any software hacker will testify to, mods aren’t limited to hardware. But you don’t have to be a master programmer to do a software mod, which might be as simple as defeating programs that can cause conflicts or erratic behavior. As an example, anti-virus software such as PC-cillin and Norton Anti-Virus can create problems with real-time software like Pro Tools LE. It’s best to disable and possibly remove antiviral software from your system before running Pro Tools LE. If you’re using drives that meet the minimum hard drive requirements and experience “disk too slow” errors, then this may be the cause.

However, there’s a need to have artificial intelligence built into the software for diagnostic purposes. If that requires a translation, consider that most error messages are uselessly generic. “Yes, indeed, there is a problem,” says the computer, “but I can’t tell you exactly why or how to fix it.” Yet system reliability is based not only on hardware and software’s ability to communicate for the intended purpose, but also on the ability to perform even when the electron goddess is unhappy.

The downside of these problems, once discovered, is that it reduces user confidence to the point where each new problem makes you wonder whether the original problem was truly resolved. I learned this many years ago when one of my modular patchbays was being installed. If I discovered one wiring error on-site, the investigation started at the patchbay, even though the problem was elsewhere.

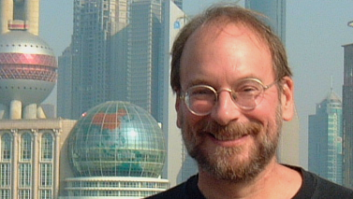

Eddie is growing his sideburns so his outside is as mod as his inside. Visit

www.tangible-technology.com

and see the fuzz.