The basic framing is started.

The basic framing is started.

The framing has spread to the back walls, which will hold the two corner bass traps and diffusor in the middle.

The framing has spread to the back walls, which will hold the two corner bass traps and diffusor in the middle.

Most of the room’s original outlets were extended out to fit the finish frame.

The live room was a constant struggle to keep clean and orderly.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The framing of the new control room took about 12 days, and once in place it was time to start stuffing the walls with Owens Corning unfaced batt insulation.

The lighter-looking insulation is Owens Corning unfaced batt insulation and the darker insulation is Owens Corning 703 unfaced ridged insulation. The cloud frame has also been added.

All the 703 ridged insulation has been placed over the batt insulation and the Realtrap bass traps have been added. This is what the back wall would look like if you took away all the fabric walls.

All the 703 ridged insulation has been placed over the batt insulation and the Realtrap bass traps have been added. This is what the back wall would look like if you took away all the fabric walls.

All the 703 ridged insulation has been placed over the batt insulation and the Realtrap bass traps have been added. This is what the back wall would look like if you took away all the fabric walls.

A few different shots of the room with the bass traps covered.

A few different shots of the room with the bass traps covered.

A few different shots of the room with the bass traps covered.

A few different shots of the room with the bass traps covered.

New paint job on the front wall.

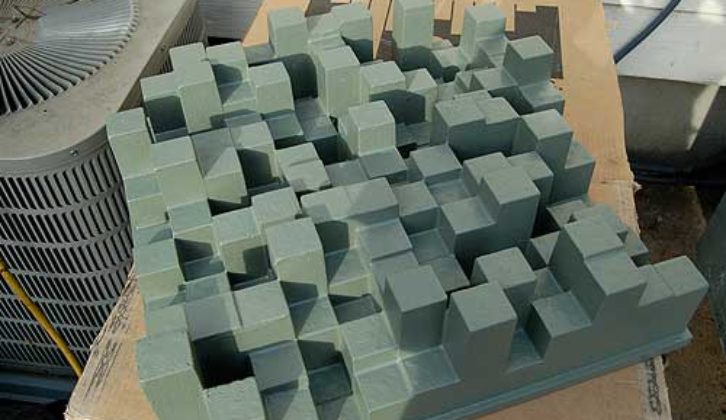

The RPG diffusors had to be painted outside using a spay gun (which was prone to clogging and would stop working because of the cold air).

The RPG diffusors had to be painted outside using a spay gun (which was prone to clogging and would stop working because of the cold air).

The cherry slats that ended up on the side walls. Before and after being finished. All the cherry wood that was used came from contractor John Ambrosi’s back yard.

The cherry slats that ended up on the side walls. Before and after being finished. All the cherry wood that was used came from contractor John Ambrosi’s back yard.

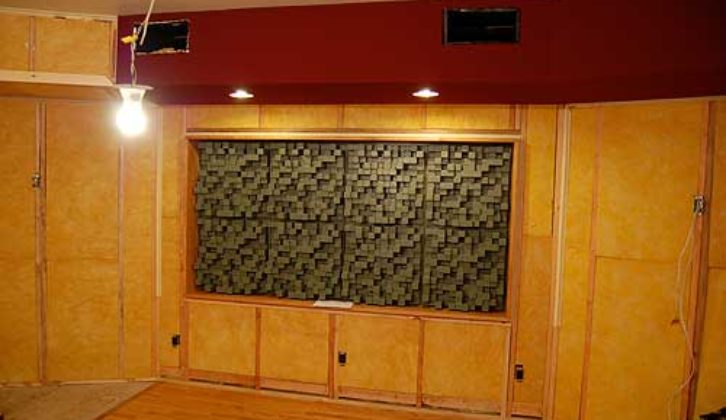

The RPG diffusors are installed, along with the fabric tracks. Fabric is then stretched from frame to frame to cover up the Fiberglas.

The RPG diffusors are installed, along with the fabric tracks. Fabric is then stretched from frame to frame to cover up the Fiberglas.

The RPG diffusors are installed, along with the fabric tracks. Fabric is then stretched from frame to frame to cover up the Fiberglas.

The RPG diffusors are installed, along with the fabric tracks. Fabric is then stretched from frame to frame to cover up the Fiberglas.

The RPG diffusors are installed, along with the fabric tracks. Fabric is then stretched from frame to frame to cover up the Fiberglas.

The new floor sanded and finished (and very shiny).

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The brand-new credenza was built by master carpenter Jeff Baker, and was made with a mixture of cherry and bamboo wood. The credenza and new console are brought in through the window and set up. With the console now in the room, the contractor (Ambrosi) could finish construction by day, and by night Kaleidoscope’s Sal Mormando and Karli Maloney could start the basic wiring for the console.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

The rest of the fabric is stretched to cover the front ceiling, cloud, back walls and around the ducts.

he new API Legacy Plus all assembled and ready for action.

The new API Legacy Plus all assembled and ready for action.