This article originally appeared in the November 2019 issue of Pro Sound News. Innovations is a monthly column in which different pro audio manufacturers are invited to discuss the thought process behind creating their products of note.

The idea of quantifying the sound absorption of different surfaces dates back to the late 19th century with the work of architectural acoustics pioneer Wallace Clement Sabine. However, acoustic treatment as part of the pro audio industry remained a forgotten, or at least ignored, science until nearly the end of the 20th century, when it finally started gaining traction among the general population of music and audio professionals.

Today, most musicians and audio workers accept acoustic treatment as a necessity in their studios and workspaces. Despite this acknowledgement, however, acoustic product development hasn’t really kept up with the pace of change of other pro audio products. The common acoustic solution continues to be a piece of foam or mineral fibers attached to a solid surface, also known as the acoustic panel.

Not only has acoustic treatment design stayed relatively stagnant, but the cost of quality treatment has not fallen the way other pro audio technologies have, such as audio processing and D/A conversion. People looking to save money often take a do-it-yourself approach to acoustic treatment, even if they know very little about the science of sound absorption.

After many years as an audio engineer in Europe, I wanted to do something about these problems. I founded EZ Acoustics in 2010 with a simple guiding principle: more acoustics for less money. We have always strived to create effective, reliable and cost-effective acoustic treatment. That philosophy has carried us along as we’ve expanded operations into 18 countries and serve many more across Europe, Asia and Africa as one of the largest international suppliers.

Related: Small-Space Acoustics, Part 2, by Steve Harvey, May 20, 2013

The goal of “more acoustics for less money” never lets us rest on our laurels. As we expanded into the United States—which we did in May 2017—we wanted to take the next big step in offering high-performance acoustic treatment to customers on any budget.

Thinking about, researching and developing products that deliver the same or better acoustics at more affordable prices led our engineers years ago to the idea of using air—yes, the most basic and common ingredient around—as a benefit. We were anxious to begin developing products that use an air cavity as part of an acoustic absorbent. We just needed to find the right time once EZ Acoustics was established.

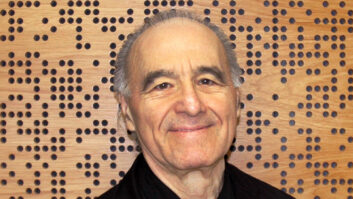

Then at the 2018 NAMM Show in Anaheim, CA, we met a living legend of acoustic research, Peter D’Antonio, Ph.D., at the annual TEC Awards ceremony. Peter played a key role in the acoustic awakening of the late 20th century. After developing a widely adopted design for recording studios at Underground Sound in Maryland in 1974, he led virtually the entire sound diffusion industry by commercializing sound diffusing surfaces in 1983 with his company, RPG Diffusor Systems. Besides that, Peter has registered multiple patents for varieties of number-theoretic, fractal and optimized diffusing and absorbing surfaces.

Related: Studio Showcase: Blackbird Studio Nashville, by Steve Harvey, Aug. 28, 2019

From that very first conversation in Anaheim, Peter and I connected on a number of shared ideas for innovations in pro audio goods. It turned out he also had an idea for using strategic air cavities in acoustic materials. He introduced us to Variable Depth Air Cavity (VDAC) technology, which provides minimum point-of-contact with the mounting surface, so most of the foam can be positioned away from the wall for optimum absorption.

Since that revelatory moment, it was clear that EZ Acoustics had to collaborate with Peter on VDAC products. That collaboration has led to a new line called Signature Series by Peter D’Antonio. So far, the Signature Series includes ProFoam, which is used for medium- to high-frequency absorption, and ProCorner, the equivalent of a corner bass trap for low frequencies.

While EZ Acoustics had created some prototypes of air-cavity products in the early years of the company, Peter’s new designs were much better than those previous attempts, improving on the efficiency and sound absorption of the acoustic material.

ProFoam is made with a layer of foam only 1 inch thick, compared to competing foam wedges that use 2 inches of material. Even with 50 percent less foam, ProFoam scores a better absorption coefficient of 0.85 NRC (noise reduction coefficient), compared to 0.8 NRC. The drastic reduction in material also helps keep the price down. The ProCorner product benefits from VDAC technology and scores an NRC of 1, promising total absorption across the audio spectrum.

Besides better performance from its VDAC, ProFoam features a second big innovation. Nested technology allows users to stack layers of foam on top of one another, expanding the array of absorption. This capability lets people expand their absorption levels without wasting the acoustic material they already have.

Related: New Orleans Museum Mints New Music, by Steve Harvey, Nov. 10, 2015

Most of EZ Acoustics’ previous air cavity designs lacked this nested, stackable technology that makes the Signature Series by Peter D’Antonio so versatile. Also, the optimized design of these new products creates a minimal amount of foam waste, which makes them more environmentally friendly. All of these various benefits add up to what we think is a true revolution in acoustic treatment.

As EZ Acoustics expands its presence throughout the United States, I’m very excited for our new users to take advantage of the innovations in the Signature Series by Peter D’Antonio. I hope that “more acoustics for less money” can become more than just a company motto, but rather a movement for the acoustic treatment world—one that will lead to affordable yet efficient results.

Marc Viadiu is the founder and chief engineer of EZ Acoustics.

EZ Acoustics • www.ezacoustics.com

Want more stories like this? Subscribe to our newsletter and get it delivered right to your inbox.