DAT machines are still a repairable item in 2004. The shift fromabsolute to timecode (TC) repairs reveals a trend among two groups:those who can afford to “wade out” a new technology waveand those who must jump in and ride the wave to shore. Either way,people are keeping their TC portables in shape for both primary andbackup duty. We’re slowly reaching the end of DAT’s lifecycle; in a fewyears, the technology will be passed from the recording domain to thatof archivists.

Compared to the consumer marketplace, pro audio is still smallpotatoes, and within it, location and post-production make up thelatest in-transition micro-niche in an already specialized industry. Ionly state the obvious because DAT is the best example of trickle-uptechnology, “prosumer”-ized by adding features like TC andXLR connectors. The next wave is borrowing heavily from affordablecomputer technology combined with some very customized electronics.Consider DAT to be the last tangible “format” —everything in the future will be virtual. But that’s for a futurearticle.

I’m not sure how many users will invest $5,000 to $15,000twice for a pair of DAT replacements, but that willhappen over time. Just as the 4mm format successfully challenged the¼-inch Nagra, analog is still alive after all these years. Atpress time, dozens of industry professionals braved record-breakingJanuary temps, meeting at New York’s Silvercup Studios to discuss thematter. Check out www.gothamsound.com for pix and videos and therec.arts.movies.production.sound newsgroup for feedback. Consumer gearmay be disposable, but pro gear is still an investment.

PUBLIC ENEMY

Keeping DAT alive requires just more patience than before. Failureswere initially mechanical, but now, electronics contribute to theworkload. Capacitors have always played a key role in the agingprocess, going all the way back to the vacuum tube era. Miniaturizationvia large-scale — and application-specific integrated circuits(LSICs and ASICs, respectively) increased the feature set, reducingmany common failure modes while creating a potential killer. Heat isenemy number one, reducing the life span of capacitors and batteries inparticular; more concentrated heat (especially in portables) alsoaffects everything from component life to solder connections.

Of all capacitor types, electrolytic caps age the least gracefully.Not only do values change, but caps can also leak acidic chemicals ontothe printed circuit board (PCB), which occasionally occurs in theFostex PD-2. The same is true for some coin-style batteries,particularly in Tascam’s DA-88. Time and repeated temperature changesaffect solder connections, too. For surface-mount devices (SMDs), alower melting-point solder is used, which is softer than the 60/40lead/tin combo of the vacuum tube era. The best advice is to send yourmachine in for routine service rather than tolerate intermittentproblems. My motivation is the hope of catching a little problem beforeit creates a big problem.

RATTLE AND HUM

No matter what the product is, a rattle is not okay. A loose screw,spring or piece of plastic may be the cause, and while the latter isrelatively benign, any metal bits can potentially short circuits withunpleasant consequences. Simply pop the cover and shake the unit upsidedown over a large white cloth to confirm success. (Springs and plasticbits are most likely to come from cassette shells, so be gentle whenhandling the,.) If nothing comes out, then it might be time to visit aspecialist.

FLUX FOR YOU

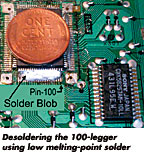

A while ago, I demonstrated a technique to extract and replace SMDsby using conventional soldering equipment with a kit that includedliquid flux and a low melting-point solder. The kit is distributed byChipQuick and is available from many electronic suppliers. The flux isawesome and applicable to other difficult-to-solder applications. Ilearned the mechanics of the process from a Sony instructional videothat was Peter Florance of Audio Services loaned me.

I didn’t initially realize that the low melting-point solder was forde-soldering. Extremely brittle when cool, the trick is to applyit to all of the legs on a chip. The solder stays molten long enough— even on a 100-pin chip — to allow the legs to lift offwithout damaging the “pads.” The chip may also be gluedinto place, so be prepared for a sudden pop that can send molten solderall over the board and in your face.

POSTAGE STAMP REPAIRS

The most challenging TC portables are the Fostex PD-2 and the HHBPDR-1000. The Fostex is a rather heavy unit. Inside, all of thecritical PCBs are rigidly mounted. The HHB is smaller and lighter, butby being much more compact, more disassembly is required and as such,the thinner PCBs are subject to flexing that can loosen solderconnections. Built as a single-box tape machine about the size ofTascam’s DA-P1, an optional TC module is mounted directly below so thatthe two become one.

One PDR-1000 that smoked before being brought in for service wascaused by overly tight cable ties on a wire harness in the TC unit.Because normal procedure is to remove the TC module for transportmaintenance, the cause was not immediately apparent. Common wear itemsfor the PDR-1000 are mechanical: sticky brake shoes and stretchedtreading belt. Changing shoes requires transport extraction, includingdisconnecting a half-dozen subminiature connectors, forcing the tech toclosely inspect all for potentially cold solder joints. This requires ajeweler’s magnifying loupe and a very small screwdriver.

TROUBLESHOOTING 101

I wish my job was as easy as inspecting wire harnesses and as simpleas replacing worn items! Once this unit was mechanically functional,the first evaluation tape played five or 10 minutes before beinginterrupted by an alarming distortion. After touching up more coldsolder joints and checking all of the various power supply voltages, afew caps were found to be outside their typical 20-percent toleranceand replaced. So far, all of the extra work turned out to bepreventive, as the unit is still intermittent.

By testing the AES output, one of two DSP chips was confirmed to begood, pointing to the D/A converter as driven by the I/O switchingcircuitry. Bingo! The “switch” was thermally unstable. Theapplication of cold and heat can sometimes help localize a problem. Forexample, I recently located a bad surface-mount cap in an Alesis M20head amplifier in this way, but the HHB only responded to a power cycleand not to the cold shoulder or the hot flash.

The next obstacle occurred during an attempt at record alignment,but there was no confidence output (the ability to monitor the signalfrom tape via the extra pair of heads for which there is a separatepreamp and DSP). When the RF signal was confirmed, the next logicalsuspect was the slave DSP, a postage-sized Sony ASIC pin around itsperimeter. Changing the chip was the trick!

Regarding the use of cable ties, many installers use a tool thatautomatically tightens the bundle and snaps the excess plastic. For theHHB’s TC unit, high tension pinched the insulation to the point whereit was too thin to be useful. I’ve never used that tool becauseit leaves a sharp edge that cuts like a razor. Diagonal cutters make aclean, safe and flush cut. Snake-oil cable fanatics take note:Over-tightened cable ties can also reduce capacitance and increasereflections in signal critical wiring.

THE SOFTER WRAP

Service techs see the world from the inside out, which is a bizarreenough perspective on its own. With the exception of vacuum tube anddiscrete transistor gear (modern or otherwise), just about everythingelse has shrunk to the point of being almost unserviceable. Butcontrary to belief, miniaturization and the highly specialized toolsrequired to make such repairs are not an obstacle, as long as the itemin question has maintained its value.

Eddie requires special looking glasses and is partial to bunnyrabbits and smiling cats. Visit him atwww.tangible-technology.com.